No products in the cart.

+86 180 5011 3692

+86 180 5011 3695

info@vialpackaging.com

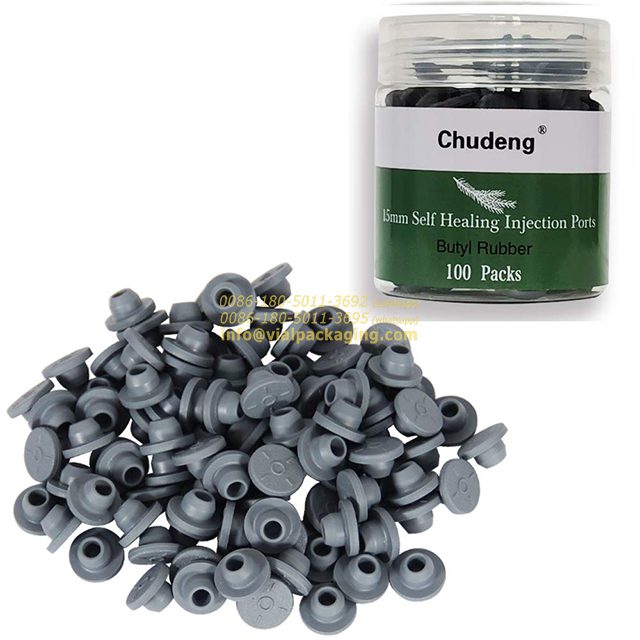

Butyl rubber stopper is the rubber stopper of Xilin bottle and all pharmaceutical factories.

The surface of the stopper is covered with film, which can effectively reduce the absorption, adsorption, leaching and penetration between the stopper and the drug, improve the long-term stability of the drug and improve the mechanical lubricity of the stopper.

$9.99

| Material | 250G Laser cardboard |

| Size | 32mm/20mm/13mm |

| Processing Service | Moulding |

| Color | Gray and Red |

| MOQ | 100 pieces |

| Sample | FREE Sample is Available |

| Lead Time | 7-9 working days |

| Delivery Time | 5-7 working days |

| Use for | injection bottles and glass via |

| Packing | PE bag |

| Shipping Services | By Fedex or DHL |

| Design | Customized |

Butyl rubber bottle stoppers have good internal cleanliness, chemical stability, air tightness and biological properties. However, due to the complex formula and the concentration gradient of raw materials added, they are absorbed, adsorbed, leach and permeate by drugs after being packaged with some drugs with relatively strong molecular activity, resulting in compatibility problems between rubber stoppers and drugs. More prominent are some cephalosporins, some large infusion, and more Chinese medicine injection preparations. Therefore, by choosing an inert soft coating to cover the surface of the rubber stopper, the direct contact between the drug and the rubber stopper is isolated, which can significantly improve the compatibility with the drug. By the end of 2004, all medicinal rubber plugs (including rubber plugs for infusion, oral liquid and other dosage forms) shall be stopped from using ordinary natural rubber plugs; All pharmaceutical rubber stoppers must use butyl rubber stoppers.

Material requirement

1) Very low gas permeability.

2) Strong resistance to water vapor transmission.

3) High chemical resistance.

4) High heat resistance aging.

5) With a high degree of internal cleanliness.

6) Good ozone resistance and weather resistance.

7) Stable radiation detoxification.

8) Should be non-toxic, tasteless, no pollution.

9) It should have good elasticity.

Copyright © Vial Packaging rights reserved.