No products in the cart.

+86 180 5011 3692

+86 180 5011 3695

info@vialpackaging.com

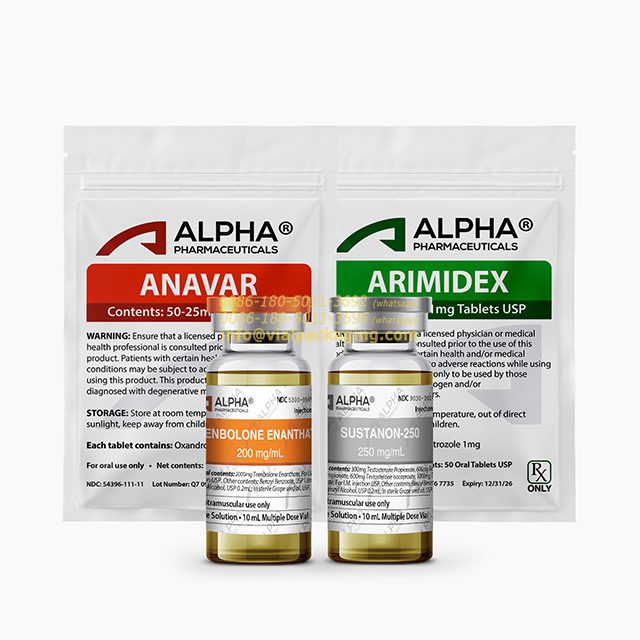

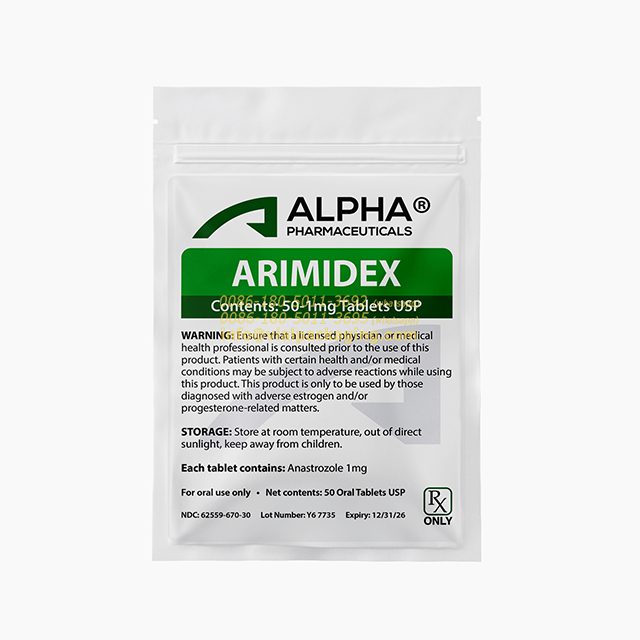

Aluminum foil bags are used for pill and pill packaging to prevent the medicine from getting damp and seeing light.

The plastic bottle is generally not afraid of moisture to avoid light drugs, and the aluminum plastic packaging is small and easy to carry.

$9.99

| Material | PET+AL+PE |

| Size | 8*12cm+6cm or Customized/ |

| Printing | Up to 9 Colors |

| Products Range | Vacuum bags, Free shaped pouch, Stand up spout pouch, Three side seal bag, Quad seal bag, Stand up zipper bag, Roll film packaging ,Aluminum foil bags, Kraft Paper Bag,Flat bottom bag |

| Useage | Used to store food, jewelry, medicine, cosmetics, powder and so on |

| Price | Large Quantity Has More Discounts |

| Payment Term | T/T 30%deposite +100%cylinder charge ,the 70% balance shipment before/ Western Union / Money Gram / Paypal |

| Certificate | ISO9001,CE , SGS ,FDA,BRC |

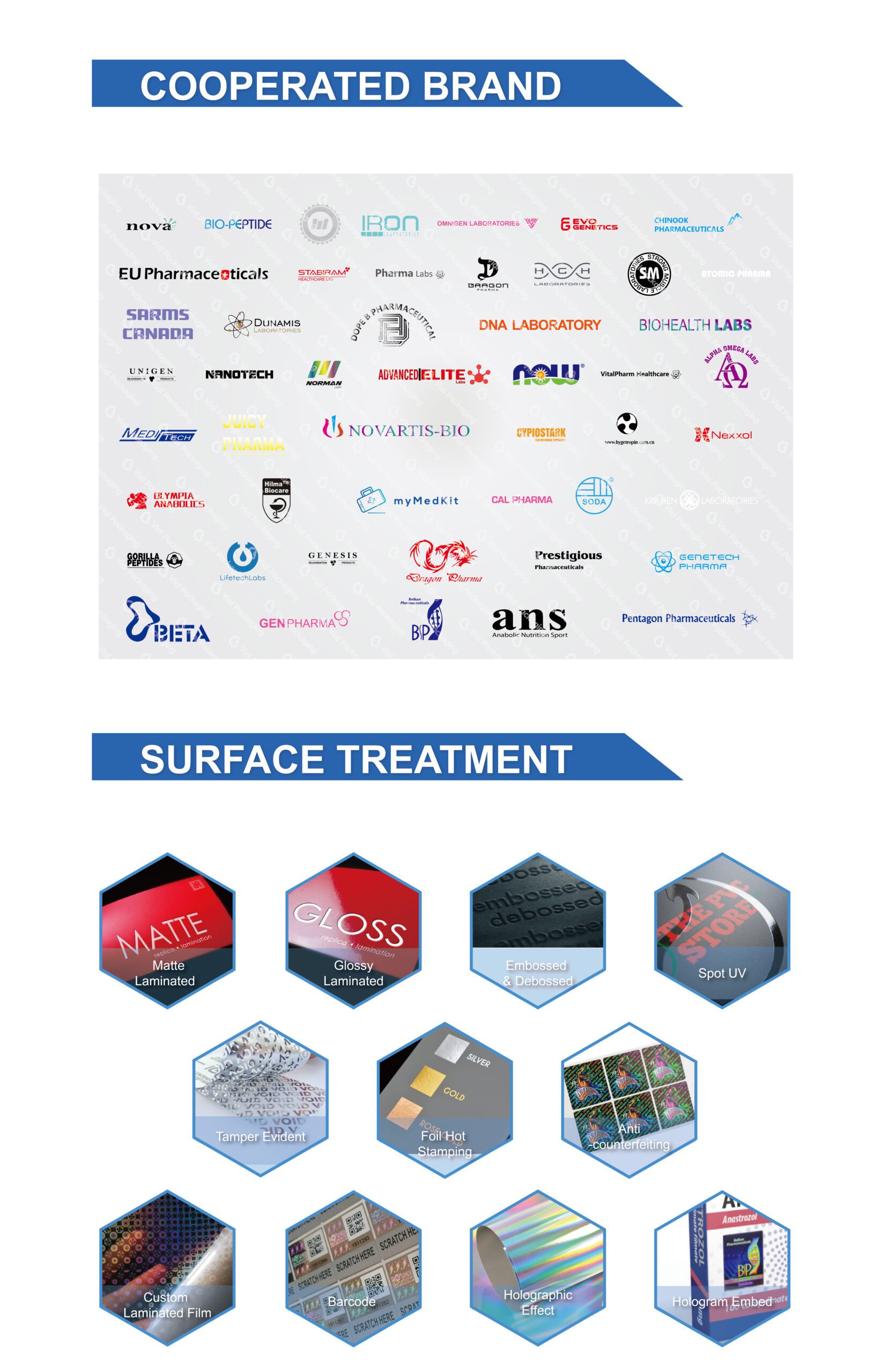

| Surface Handing | Gravure Printing |

| Samples | Various Types Are Available |

The brief process of pharmaceutical aluminum foil bag printing is as follows:

Aluminum foil unwinding → gravure printing → drying → protective coating → drying → adhesive coating → drying → Aluminum foil unwinding.

Printing inks for pharmaceutical aluminum foil bags are currently mainly divided into two categories: one is polyamide ink. This ink has good adhesion, dispersion, gloss, wear resistance, solvent resistance and softness for the printing of various substances, and is mainly used for the printing of plastic films. When used in the printing of aluminum foil materials, the excellent properties of the ink can be shown, and its heat resistance can also meet the requirements of aluminum foil printing. The second is a special ink for aluminum foil based on vinyl chloride-vinyl acetate copolymer synthetic resin/acrylic resin as the main component. Its coloring point is bright color, high concentration, especially strong adhesion with aluminum foil and good transparency. However, when used for gravure printing, the solvent is volatile, and when used for medical PTP aluminum foil surface printing, it is easy to cause ink drying and deposition in the gravure roller ink hole, resulting in plate paste phenomenon. Therefore, it is necessary to pretreat the ink deposition freezing, which is to stir the ink deposition freezing or increase the temperature (water bath). If the ink is stored for too long, the ink will be deposited, resulting in more resin solution on the upper layer of the ink, more pigment on the lower layer, a light upper layer, and a dark lower layer. It should also be used after mixing well.

The inside of the medicine aluminum foil bag is coated with PTP aluminum foil adhesive, which is used to firmly press the aluminum foil and the medical polyvinyl chloride hard sheet together, and isolate the drug in the plastic foam cap from the outside world, so as to achieve the purpose of sealing the medicine. In the process of adding drugs for heat sealing, the bonding layer is activated by hot pressing and firmly bonded to the PVC plastic sheet. The bonding layer and PVC resin require good thermal sensitivity and substrate compatibility.

Copyright © Vial Packaging rights reserved.